Latest News

Revolutionizing Water Treatment: Anionic Emulsion Polyacrylamide's Role in Purification

2024-04-26

Revolutionizing Water Treatment: Anionic Emulsion Polyacrylamide's Role in Purification

2024-04-26

Understanding Anionic Emulsion Polyacrylamide

2024-04-08

Understanding Anionic Emulsion Polyacrylamide

2024-04-08

Enhancing Oil Recovery Processes with Powder Anionic Polyacrylamide

2024-03-27

Enhancing Oil Recovery Processes with Powder Anionic Polyacrylamide

2024-03-27

Impact of Powder Anionic Polyacrylamide in Enhancing Papermaking Processes

2024-03-25

Impact of Powder Anionic Polyacrylamide in Enhancing Papermaking Processes

2024-03-25

Navigating Environmental Stewardship: The Impact of Polycrylamide Emulsions

2024-03-23

Navigating Environmental Stewardship: The Impact of Polycrylamide Emulsions

2024-03-23

Finding the Perfect Compatibility: Polycrylamide Emulsions and Other Chemicals

2024-03-21

Finding the Perfect Compatibility: Polycrylamide Emulsions and Other Chemicals

2024-03-21

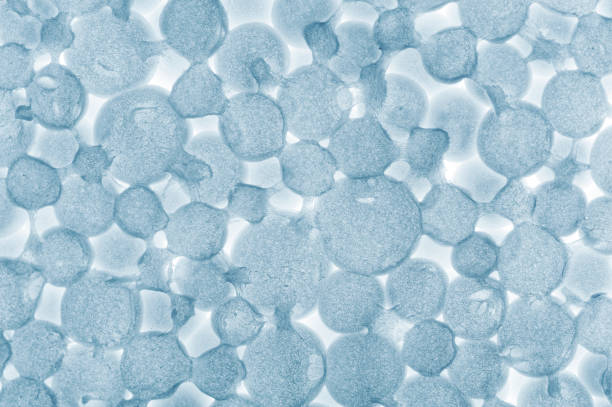

Cationic polyacrylamide is a high-molecular-weight, long-chain polymer formed by the polymerization of acrylamide. It can dissolve well in water and organic solvents such as acetic acid, ethylene glycol, glycerol, and amines. As an important and widely used water-soluble polymer, its actual form in water is a random coil. Due to the presence of certain amide groups in the random coil with specific particle size and surface, it exhibits bridging and adsorption capabilities, providing it with certain flocculation capabilities. It also possesses valuable properties such as flocculation, thickening, shear resistance, drag reduction, and dispersion. Due to different ionic characteristics, these properties have different emphases and are increasingly used in many industrial processes.

In raw water treatment, it is combined with activated carbon for coagulation and clarification of suspended particles in domestic water. Substituting organic flocculants such as acrylamide for inorganic flocculants improves the water treatment capacity by over 20%, even without modifying sedimentation tanks. In wastewater treatment, cationic polyacrylamide enhances the utilization rate of water in recycling and can also be used for sludge dewatering. It is a vital component in industrial water treatment formulations, contributing to various processes.

When achieving the same water quality, cationic polyacrylamide PAM can be used as a coagulant aid with other flocculants, significantly reducing the dosage of flocculants. Combining cationic polyacrylamide PAM with other flocculants as a coagulant aid can greatly reduce the dosage of flocculants while maintaining the same water quality. Cationic polyacrylamide PAM improves water quality. In drinking water treatment and industrial wastewater treatment, its combination with inorganic flocculants noticeably enhances water quality.

Cationic pam enhances floc strength and settling speed, improving solid-liquid separation efficiency, beneficial for sludge dewatering in circulation cooling systems. Its use significantly reduces the dosage of inorganic flocculants, preventing deposition of inorganic substances on equipment surfaces and slowing down corrosion and scaling of equipment.

The different properties of sludge directly affect treatment effectiveness, with higher solid content requiring larger amounts of conditioning agents.

Lower temperatures slow down hydrolysis, leading to reduced treatment efficiency. In winter, especially in colder regions, higher doses of the treatment are needed.

Cationic pam series products, being large-chain polymers with a coiled structure, undergo a swelling process in water. Typically, the preparation time requires continuous stirring for approximately 50 minutes. Non-ionic products and low cationic pam have a slower dissolution rate, generally exceeding 60 minutes.