Latest News

Revolutionizing Water Treatment: Anionic Emulsion Polyacrylamide's Role in Purification

2024-04-26

Revolutionizing Water Treatment: Anionic Emulsion Polyacrylamide's Role in Purification

2024-04-26

Understanding Anionic Emulsion Polyacrylamide

2024-04-08

Understanding Anionic Emulsion Polyacrylamide

2024-04-08

Enhancing Oil Recovery Processes with Powder Anionic Polyacrylamide

2024-03-27

Enhancing Oil Recovery Processes with Powder Anionic Polyacrylamide

2024-03-27

Impact of Powder Anionic Polyacrylamide in Enhancing Papermaking Processes

2024-03-25

Impact of Powder Anionic Polyacrylamide in Enhancing Papermaking Processes

2024-03-25

Navigating Environmental Stewardship: The Impact of Polycrylamide Emulsions

2024-03-23

Navigating Environmental Stewardship: The Impact of Polycrylamide Emulsions

2024-03-23

Finding the Perfect Compatibility: Polycrylamide Emulsions and Other Chemicals

2024-03-21

Finding the Perfect Compatibility: Polycrylamide Emulsions and Other Chemicals

2024-03-21

In the realm of mining operations, the use of chemicals plays a crucial role in various processes. One such chemical class that is widely employed is mining flocculants. These substances are specifically designed to aid in the separation of solid particles from liquid suspensions, improving the efficiency and productivity of mining operations. In this article, we will explore the types and uses of mining flocculants, shedding light on their importance within the mining industry.

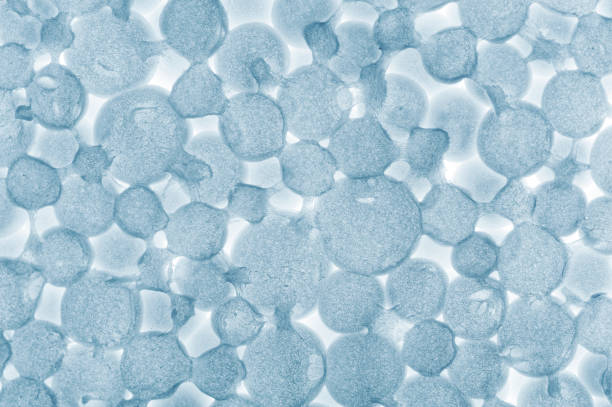

Before we delve into the various types and uses of mining flocculants, let's understand what they are. Mining flocculants are chemicals that promote particle aggregation or flocculation in a liquid-solid separation process. They work by causing suspended solids to come together and form large clusters, facilitating their settling or separation from the liquid phase.

Mining flocculants can be classified into two main categories based on their nature and composition: inorganic flocculants and organic flocculants.

Inorganic Flocculants

Inorganic flocculants, such as polyaluminum chloride (PAC) and aluminum sulfate (alum), are commonly used in mining operations. PAC is effective in bridging and floc formation, whereas alum works by neutralizing the charge on suspended particles. These types of flocculants are preferred for their cost-effectiveness and wide availability.

Applications of inorganic flocculants in mining include:

Settling of tailings: Flocculants are used to settle and thicken tailings, thereby reducing the volume of waste material and improving water recovery during the mining process.

Water clarification: Inorganic flocculants aid in the removal of suspended particles from water sources, ensuring improved water quality for various mining activities.

Solid-liquid separation: They assist in the separation of solids from liquid slurries, enabling efficient processing of minerals and ores.

Organic Flocculants

Organic flocculants, such as polyacrylamides (PAM) and starch-based polymers, are widely utilized in mining operations for their enhanced flocculating properties. These polymers possess high molecular weights, allowing for improved bridging and particle aggregation.

Applications of organic flocculants in mining include:

Tailings dewatering: Organic flocculants enable efficient dewatering of tailings, reducing moisture content and facilitating the handling and disposal of waste materials.

Thickening and clarification: They play a crucial role in thickening and clarifying the concentrate streams, enhancing overall efficiency and productivity.

Water recycling: Organic flocculants aid in the separation and recovery of clean water from mining wastewater, minimizing environmental impact and reducing water usage.

Mining flocculants are indispensable chemicals used in mining operations for enhancing solid-liquid separation processes. Understanding the types and applications of these flocculants is vital for mining operators to improve their operational efficiency, minimize environmental impact, and optimize resource utilization. By employing suitable flocculants, mining companies can achieve better tailings management, improved water quality, and increased productivity.