Latest News

Revolutionizing Water Treatment: Anionic Emulsion Polyacrylamide's Role in Purification

2024-04-26

Revolutionizing Water Treatment: Anionic Emulsion Polyacrylamide's Role in Purification

2024-04-26

Understanding Anionic Emulsion Polyacrylamide

2024-04-08

Understanding Anionic Emulsion Polyacrylamide

2024-04-08

Enhancing Oil Recovery Processes with Powder Anionic Polyacrylamide

2024-03-27

Enhancing Oil Recovery Processes with Powder Anionic Polyacrylamide

2024-03-27

Impact of Powder Anionic Polyacrylamide in Enhancing Papermaking Processes

2024-03-25

Impact of Powder Anionic Polyacrylamide in Enhancing Papermaking Processes

2024-03-25

Navigating Environmental Stewardship: The Impact of Polycrylamide Emulsions

2024-03-23

Navigating Environmental Stewardship: The Impact of Polycrylamide Emulsions

2024-03-23

Finding the Perfect Compatibility: Polycrylamide Emulsions and Other Chemicals

2024-03-21

Finding the Perfect Compatibility: Polycrylamide Emulsions and Other Chemicals

2024-03-21

Alumina extraction from bauxite residue has long been associated with environmental challenges and resource wastage. However, recent advancements in technology are paving the way for a sustainable transformation. One key player in this revolution is the application of red mud washer flocculants, showcasing their pivotal role in turning bauxite residue into a valuable resource.

Before delving into the impact of red mud washer flocculants, it's essential to grasp the intricacies of alumina extraction. Traditionally, this process involved significant waste generation and posed environmental risks. Red mud, a byproduct of alumina extraction, was often considered a problematic residue, requiring innovative solutions for its management.

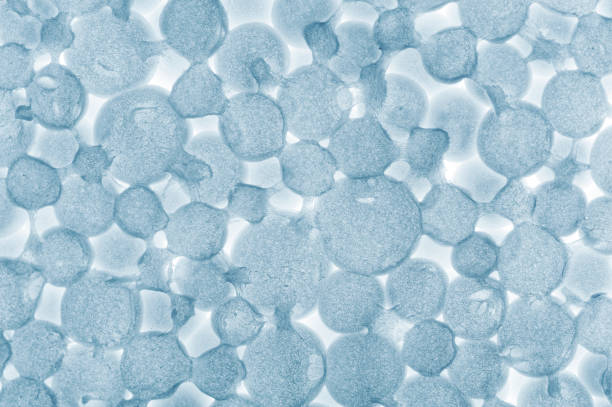

Enter red mud washer flocculants—a technological breakthrough that is reshaping the landscape of alumina extraction. These specialized chemicals play a crucial role in the separation and settling of solid particles in the red mud, enhancing the efficiency of the washing process. This not only reduces water consumption but also facilitates the recovery of valuable components from the red mud.

One of the primary benefits of incorporating red mud washer flocculants is the positive impact on the environment. With enhanced solid-liquid separation, the volume of red mud is reduced, minimizing the need for extensive storage facilities. Additionally, the recovered resources from the red mud can be utilized in various industries, contributing to a more circular and sustainable approach to resource management.

While the application of red mud washer flocculants brings about significant advantages, challenges may arise in their implementation. This section of the blog explores the potential hurdles and offers insights into overcoming them, ensuring that the alumina extraction process remains not only efficient but also environmentally responsible.

In conclusion, the integration of red mud washer flocculants in alumina extraction marks a transformative shift towards sustainability. By converting bauxite residue into a valuable resource, these flocculants are not only optimizing industrial processes but also contributing to a more eco-friendly and resource-efficient future. As industries continue to embrace these innovations, the journey from bauxite residue to resource is becoming a reality, heralding a new era in alumina extraction practices.