Latest News

Revolutionizing Water Treatment: Anionic Emulsion Polyacrylamide's Role in Purification

2024-04-26

Revolutionizing Water Treatment: Anionic Emulsion Polyacrylamide's Role in Purification

2024-04-26

Understanding Anionic Emulsion Polyacrylamide

2024-04-08

Understanding Anionic Emulsion Polyacrylamide

2024-04-08

Enhancing Oil Recovery Processes with Powder Anionic Polyacrylamide

2024-03-27

Enhancing Oil Recovery Processes with Powder Anionic Polyacrylamide

2024-03-27

Impact of Powder Anionic Polyacrylamide in Enhancing Papermaking Processes

2024-03-25

Impact of Powder Anionic Polyacrylamide in Enhancing Papermaking Processes

2024-03-25

Navigating Environmental Stewardship: The Impact of Polycrylamide Emulsions

2024-03-23

Navigating Environmental Stewardship: The Impact of Polycrylamide Emulsions

2024-03-23

Finding the Perfect Compatibility: Polycrylamide Emulsions and Other Chemicals

2024-03-21

Finding the Perfect Compatibility: Polycrylamide Emulsions and Other Chemicals

2024-03-21

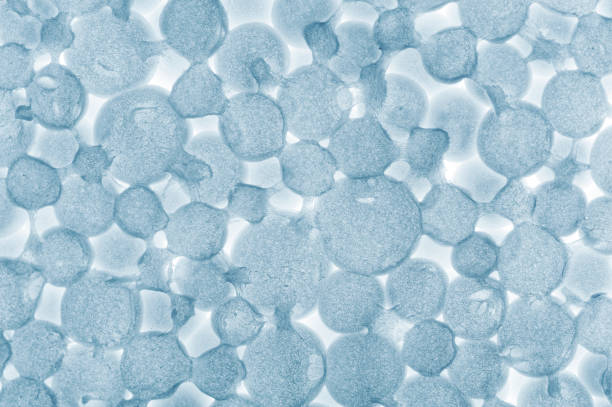

The type of polyacrylamide has many varieties. According to the ionic characteristics, it can be divided into anions, cations, and non-ionic types. Among them, acrylamide anionic has the advantages of low cost, excellent surface activity, and wide use. The method is to introduce ionized carboxyl groups into the polymer chain through the copolymerization of acrylamide and acryloyl. In addition, it can also be obtained by hydrolysis of some acid amide groups in polyacrylamide under alkaline conditions.

When the molecular weight is low, it is beneficial to increase the tensile strength of paper, and when the molecular weight is high, it is beneficial to increase the paper's resistance to breakage and folding. The composition of acrylamide anionic was studied, and different molecular weights of polyacrylamide were obtained by modifying the reaction conditions. The results showed that anionic polyacrylamide with a molecular weight of 255,000 improved the elongation-to-break of paper by 27% and the burst index by 69.4%. Anionic polyacrylamide with a molecular weight of 160,000 had a significant effect on the tearing degree and fold resistance of paper, increasing them by 92% and 13.8% respectively.

Whether it is cationic, non-ionic, or anionic, they all need to be prepared as a solution before use. Therefore, in this process, the dosage of acrylamide anionic needs to be determined through experiments based on the characteristics of different water sources and water treatment processes. Foreign literature introduces the following rules in the flocculation process of high-molecular-weight flocculants:

When the dosage of high-molecular-weight flocculant ensures coverage of the surface area of the particles, it can achieve the desired effect.

If the particle surface is over-saturated with polymer molecules, flocculation will deteriorate. This is because in this case, the free ends of high-molecular-weight flocculants can also adsorb on the same surface, forming a bent shape, thereby reducing the number of bridging connections between adjacent particles.

When the stirring intensity is strong enough to break the bonds of the polymer, the flocculated particles will disperse. If the dosage of high-molecular-weight polyacrylamide is less than the ideal dosage, the bridging connections will be weaker.

There is a linear relationship between the ideal dosage of anionic polyacrylamide and the surface area available for adsorption on dispersed phase particles. A certain water plant believes that for its severely polluted, diverse pollutants, low pH value, and low alkalinity raw water, non-ionic polyacrylamide is relatively suitable for flocculation, anionic polyacrylamide is slightly inferior, and cationic polyacrylamide performs poorly. According to flocculation theory, it is speculated that the low turbidity of the severely polluted raw water during the dry season may result in fewer particles available for bridging, and the addition of liquid chlorine before adding flocculants may have a destructive effect on cationic flocculants. The pH value of water after adding coagulants and disinfectants is generally not higher than 7.0, and the water charge is not significant. Anionic and cationic polyacrylamides do not show advantages.

In the papermaking process, the molecular weight and dosage of anionic polyacrylamide can both affect the quality of paper produced by paper mills. Therefore, it is necessary to control this aspect in order to achieve higher quality and lower cost in paper production!