Latest News

Revolutionizing Water Treatment: Anionic Emulsion Polyacrylamide's Role in Purification

2024-04-26

Revolutionizing Water Treatment: Anionic Emulsion Polyacrylamide's Role in Purification

2024-04-26

Understanding Anionic Emulsion Polyacrylamide

2024-04-08

Understanding Anionic Emulsion Polyacrylamide

2024-04-08

Enhancing Oil Recovery Processes with Powder Anionic Polyacrylamide

2024-03-27

Enhancing Oil Recovery Processes with Powder Anionic Polyacrylamide

2024-03-27

Impact of Powder Anionic Polyacrylamide in Enhancing Papermaking Processes

2024-03-25

Impact of Powder Anionic Polyacrylamide in Enhancing Papermaking Processes

2024-03-25

Navigating Environmental Stewardship: The Impact of Polycrylamide Emulsions

2024-03-23

Navigating Environmental Stewardship: The Impact of Polycrylamide Emulsions

2024-03-23

Finding the Perfect Compatibility: Polycrylamide Emulsions and Other Chemicals

2024-03-21

Finding the Perfect Compatibility: Polycrylamide Emulsions and Other Chemicals

2024-03-21

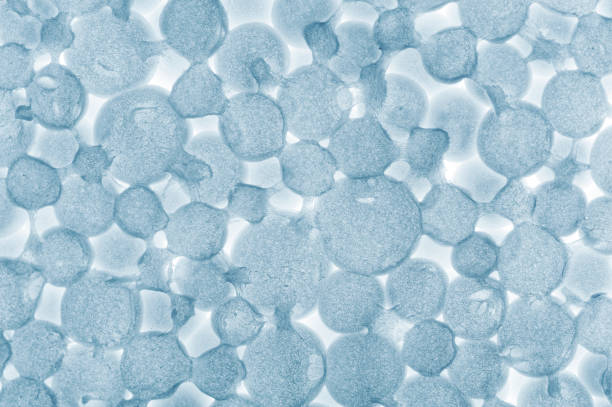

The solid-liquid separation processes within industrial settings have undergone a profound transformation with the introduction of Polyacrylamide (PAM) polymer flocculants. These highly effective agents have redefined the landscape of separation technologies, providing industries with a versatile and efficient solution to the challenges associated with separating solid particles from liquid phases.

At the heart of their effectiveness lies the unique ability of PAM polymer flocculants to induce flocculation—the process of aggregating small particles into larger, easily separable masses. This mechanism streamlines the solid-liquid separation process by enhancing the settling and filtration of suspended solids. As a result, industries witness improved clarity in liquid phases and increased efficiency in the removal of unwanted particulate matter.

PAM polymer flocculants are not a one-size-fits-all solution; rather, they offer tailored approaches to solid-liquid separation across diverse industrial applications. Whether in wastewater treatment, mining, or the chemical industry, these flocculants exhibit versatility in addressing specific challenges associated with different types of solids and liquids. The adaptability of PAM polymer flocculants ensures optimal performance in a wide array of operational scenarios.

The introduction of PAM polymer flocculants into solid-liquid separation processes significantly improves settling and filtration dynamics. The flocculated particles, now larger and heavier, settle more rapidly, expediting the separation of solids from liquids. This heightened settling efficiency translates into reduced processing times and increased throughput, ultimately enhancing the overall productivity of industrial operations.

As industries face increasing scrutiny regarding their environmental footprint, the use of PAM polymer flocculants aligns with sustainability goals. By promoting more efficient solid-liquid separation, these flocculants reduce the need for extensive water treatment processes and minimize the environmental impact associated with the disposal of chemical waste. This eco-friendly approach contributes to a greener and more responsible industrial landscape.

In water-intensive industries, the efficient separation of solids from liquid streams becomes paramount for water reuse and conservation. PAM polymer flocculants play a pivotal role in achieving this goal by facilitating the extraction of clean water from processes laden with suspended solids. The recycled water can then be reintegrated into industrial processes, reducing the demand on freshwater sources and promoting sustainable water management practices.

Stringent regulations governing water quality necessitate industries to adhere to specific standards. The use of PAM polymer flocculants ensures that solid-liquid separation processes meet or exceed regulatory requirements. This not only safeguards industries against potential legal consequences but also ensures the production of high-quality end products free from contaminants.

In conclusion, the effectiveness of PAM polymer flocculants in solid-liquid separation processes represents a paradigm shift in industrial practices. Their ability to enhance settling, filtration, and environmental sustainability positions them as indispensable tools for industries seeking optimal performance and compliance. As industries continue to evolve, PAM polymer flocculants stand as a testament to the transformative power of innovative solutions in addressing the complexities of solid-liquid separation. Through their application, industries can achieve heightened efficiency, reduced environmental impact, and a future-oriented approach to resource management.