Latest News

Enhancing Oil Recovery Processes with Powder Anionic Polyacrylamide

2024-03-27

Enhancing Oil Recovery Processes with Powder Anionic Polyacrylamide

2024-03-27

Impact of Powder Anionic Polyacrylamide in Enhancing Papermaking Processes

2024-03-25

Impact of Powder Anionic Polyacrylamide in Enhancing Papermaking Processes

2024-03-25

Navigating Environmental Stewardship: The Impact of Polycrylamide Emulsions

2024-03-23

Navigating Environmental Stewardship: The Impact of Polycrylamide Emulsions

2024-03-23

Finding the Perfect Compatibility: Polycrylamide Emulsions and Other Chemicals

2024-03-21

Finding the Perfect Compatibility: Polycrylamide Emulsions and Other Chemicals

2024-03-21

Enhancing Efficiency in Oil and Gas Drilling with Polycrylamide Emulsions

2024-03-19

Enhancing Efficiency in Oil and Gas Drilling with Polycrylamide Emulsions

2024-03-19

Production Process and Formulations of Polycrylamide Emulsions

2024-03-17

Production Process and Formulations of Polycrylamide Emulsions

2024-03-17

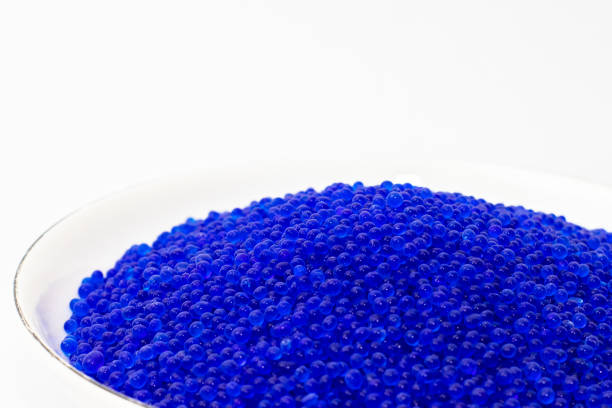

SINOFLOC red mud setting flocculants is used for settling aluminum red mud slurries in alumina plants, which provide high settling rates, better separation performance and reducing suspended solids significantly. SINOFLOC products could improve the liquor filtration operations and make the processing more economical.

|

Products |

Products Code |

Anionic Charge |

Molecular Weight |

|

SINOFLOC 9619 |

Strongly |

||

|

Red Mud Settling Flocculants |

SINOFLOC 9819 |

Strongly |

Very High |

|

Red Mud Settling Flocculants |

SINOFLOC 9919 |

Strongly |

Very High |

|

Red Mud Settling Flocculants |

SINOFLOC 9909 |

Strongly |

Medium |

|

Red Mud Settling Flocculants |

SINOFLOC 991 |

Very Strongly |

High |

Leave us Message